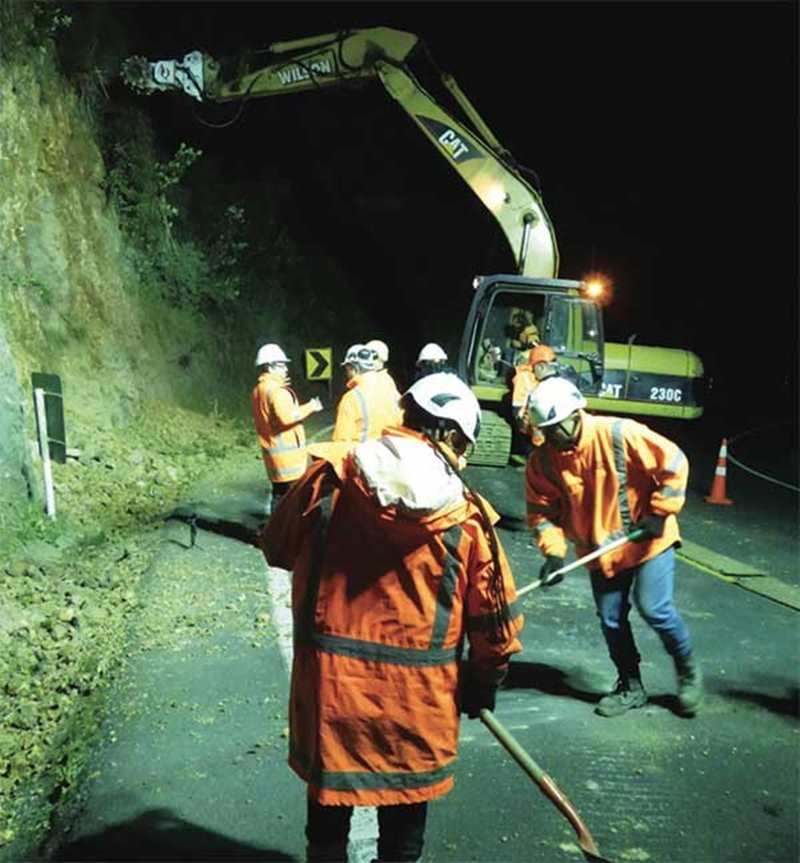

The usual practice is to sluice the loose material off with water or send an abseiler down the rock face to knock it down. This time contractors put a milling machine on the end of a long-reach digger. This required some adjustment to the hydraulics on the arm, but they tried it out in a quarry, and it worked.

The method was used over December for the first time on two 20 metre sections of SH1 on the south side of the Brynderwyn Hills.

The Antraquip AQ-3 milling head used in this innovative project was supplied by Boss Attachments NZ.

Boss managing director Paul Herbison says his client was really impressed with the performance of the AQ-3 and the way it handled the in-situ greywacke without any difficulty.